Table of Contents

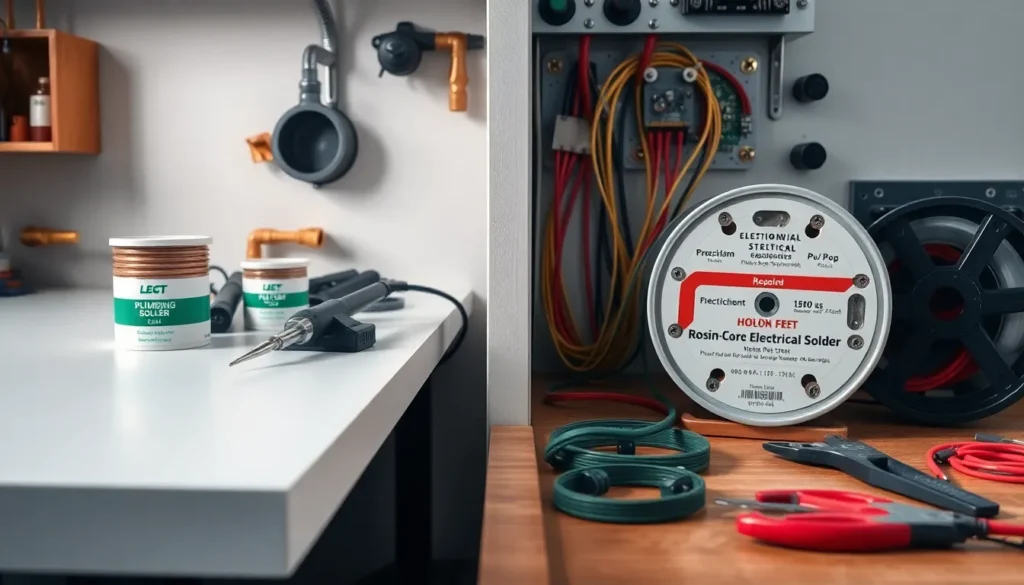

ToggleAre you ready to jump into the world of solder? Sure, it sounds like a riveting topic, but stick around: it’s more fascinating than it seems. Plumbing solder and electrical solder often pop up in DIY discussions, sending even experienced handymen scratching their heads. Both types help to create strong connections, but they have distinct purposes and properties. Let’s explore the nuances of soldering, so you don’t end up using plumbing solder on your delicate electrical projects.

Understanding Solder: What It Is and Why It Matters

Solder is a metal alloy that’s used to join two or more electronic or plumbing components together. Whether it’s pipes in your basement or wires in your wall, solder plays a crucial role in ensuring strong, lasting connections. Usually found in a convenient, spool-like form, it melts at lower temperatures, solidifying to form a reliable bond as it cools.

So, why does solder even matter? Imagine trying to fix a leaky pipe without it, or worse, attempting to troubleshoot an electrical short circuit. A poor connection could lead to serious issues, think leaks or sparks. Understanding solder is key for anyone digging into home improvement or electrical work.

Types of Solder Used in Plumbing

When it comes to plumbing, there are primarily two types of solder: lead-based and lead-free solder.

Lead-Based Solder

Although lead-based solder was once the go-to for many plumbers, its use has become increasingly restricted due to health concerns. Its malleable properties allowed easier application, but lead exposure is a no-go in modern plumbing.

Lead-Free Solder

In the present day’s eco-conscious environment, lead-free solder has taken over. Composed mainly of tin, copper, and sometimes silver, it meets the safety standards for potable water systems. Lead-free solder melts at a higher temperature but ensures safe and durable joints. This type is a wise choice for both new installations and repairs, especially in homes with a focus on health and environmental safety.

Types of Solder Used in Electrical Work

When it comes to electrical projects, the solder scene is a bit more varied. Two key categories are commonly used: rosin-core and acid-core solder.

Rosin-Core Solder

Rosin-core solder contains a flux made from natural resin, allowing it to flow easily while heating. This type is ideal for electrical applications because the rosin is non-corrosive, ensuring that the solder doesn’t degrade the connections over time.

Acid-Core Solder

While acid-core solder also does the job, it’s not generally recommended for electrical applications due to its corrosive nature. It’s primarily used for metal-to-metal applications, not for sensitive electrical components. When in doubt, sticking with rosin-core solder is best for secure and reliable connections.

Key Differences Between Plumbing Solder and Electrical Solder

Recognizing the differences between plumbing and electrical solder can save significant headaches down the line. Here are the standout features:

- Composition: Plumbing solder is commonly tin-based or lead-based, while electrical solder is often rosin core with a mix of tin and lead.

- Purpose: Plumbing solder is intended for joining pipes and fixtures, whereas electrical solder is specifically designed to establish electrical connections.

- Melting Points: Generally, plumbing solder melts at a higher temperature than electrical solder. The lower temperature of electrical solder makes it more suitable for sensitive components that could easily melt or get damaged.

- Flux Types: The type of flux used in each varies significantly: plumbing solder often uses non-corrosive fluxes due to exposure to water, while electrical solder uses rosin flux, which can be non-corrosive too but is specifically tailored for electrical uses.

These differences illustrate that using the appropriate solder for your project isn’t just a recommendation: it’s crucial.

Choosing the Right Solder for Your Project

Selecting the correct solder can feel like navigating a maze, but it doesn’t have to be daunting. Here are a few pointers:

- Consider the Project Type: If you’re working on plumbing, always prioritize lead-free solder, especially if the pipes will carry drinking water. For electrical repairs or creations, look for rosin-core solder to ensure safety and reliability.

- Examine the Materials: Different metals may require different types of solder. Know the materials you’re working with to make an informed choice.

- Quality Over Cost: While it may be tempting to save a few bucks, investing in high-quality solder will pay off in terms of durability and performance.

Safety Considerations When Using Solder

Safety should always be top of mind when soldering. Remember these essential tips:

- Use Ventilation: Ensure you’re in a well-ventilated area. Fumes from burnt solder, especially those containing lead, can be harmful.

- Protective Gear: Wearing safety goggles and gloves is a must. You wouldn’t want to ruin your vision or singe your hands.

- Lead Management: If you’re using lead-based solder, be vigilant about washing your hands after handling it. Lead exposure is serious, so keep it isolated from your living space.

- Read Labels: Knowing what goes into your solder will help you understand any potential risks. Always follow safety guidelines mentioned on the packaging.